©copyright by Beijing Huadu Chemical Building Materials Group. All Rights Reserved.

Add:1-4-304A, 69 Chaoyang Road, Chaoyang District, Beijing 100024

京ICP备2023025914号

京ICP备2023025914号

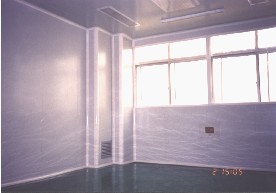

HDCC-940MM for Cleaning and Processing Room

| Surface Materials | |

|

Surface Materials |

Thickness(mm) |

|

Plasticised zinc steel |

0.6-0.8 |

|

Plasticised alu. steel |

0.6-0.8 |

|

Aluminium alloy |

0.6-1.0 |

|

Stainless steel |

0.6-1.0 |

|

FRP |

1.3-2.5 |

|

ABS |

1.0-2.5 |

|

PVC |

1.0-2.5 |

The most important factor to influence the quality of the construction, even to the finished products, is how to select materials for the cleanroom envelope.

Huadu Maohua Cleaning and Processing Room Panels are pre-fabricated in plant and have the following characters:

· air-tight, thermal insulation and water-humid proof.

· anti static electricity, and dust free.

· anti chemical corrosion, and long time service life

· could be flushed, and easy clean

· good strength performance

· acoustic-proof

Surface type: Double-side metal, both flat for each side.

Effective width: 940mm

Thickness of insulation: 60mm,80mm,100mm

|

Core Foams and Properties |

|||||

| Items | Core Insulation | ||||

| PU | EPS | XPS | Phenolic Foam | ||

| Density(kg/m3) | 42±2 | 18±1 | 28 | 45 | |

|

Compressive Strength |

kpa | 174 | 136 | 250 | 120 |

|

Flexural Strength |

315 | 232 | ---- | 270 | |

| Thermal ConductivityW/(m.k) | 0.024 | 0.033 | 0.027 | 0.028 | |

|

Water Absorption %(V/V) |

2.45 | 0.75 | 0.50 | 2.50 | |

|

Dimensional Stability at 70~-40℃ |

% | ±0.5 | |||